THE INDUSTRY WORKHORSE

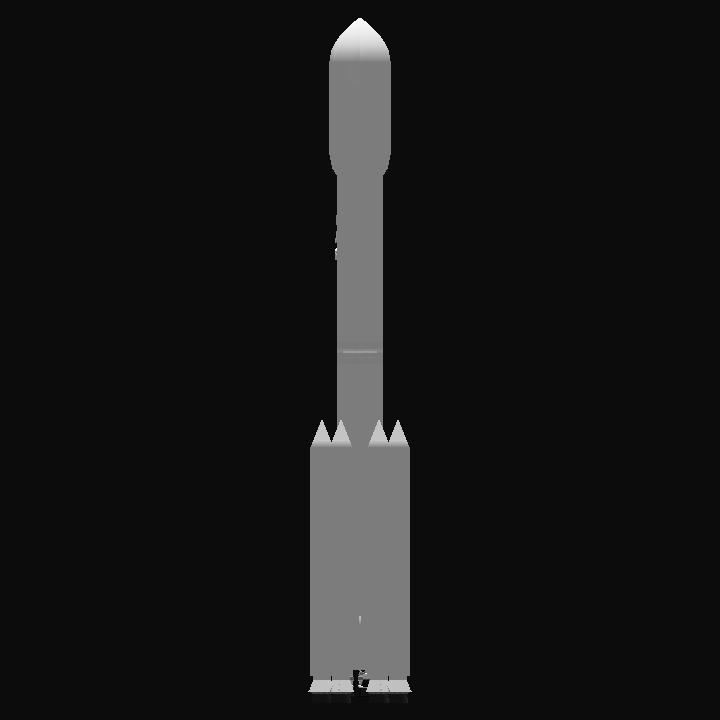

DELTA II

HERITAGE OF SUCCESS

THE INDUSTRY WORKHORSE

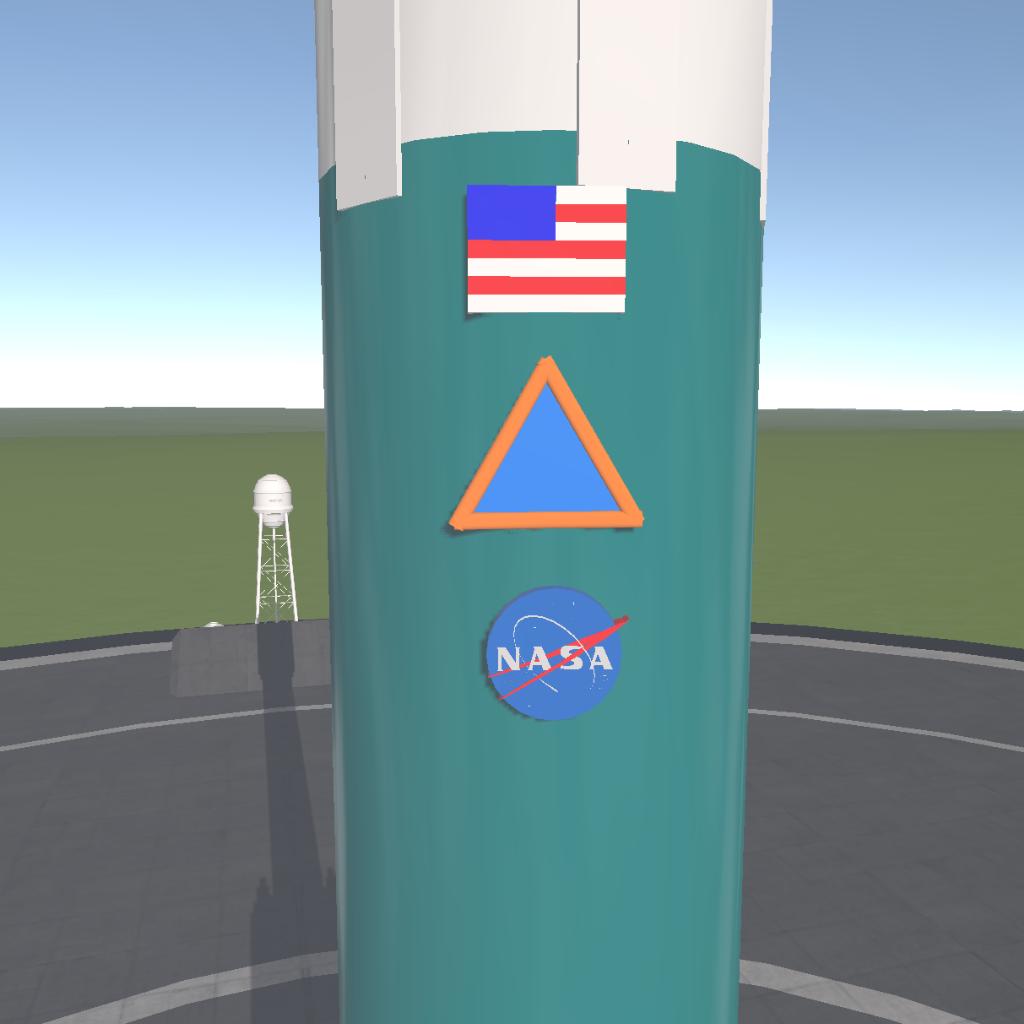

The Delta II program has a rich history. Over 29 years, the rocket launched 155 times with 100 consecutive successful missions, culminating in the final ICESat-2 flight for NASA.

Delta II has launched many memorable missions including NASA’s rovers Spirit and Opportunity, the Phoenix Mars Lander, all operational GPS missions through the constellation of 21 GPS II-R missions for the Air Force, and commercial missions for Iridium, Globalstar and three DigitalGlobe satellites. This tremendous achievement is a tribute to the dedicated ULA employees and supplier teammates that ensure mission success is the focus of each and every launch.

PAYLOAD FAIRINGS

The Delta II launch vehicle offers the user a choice of three fairings: a 2.9-m (9.5-ft)-diameter skin-and-stringer center section fairing (bisector), and two versions of a 3-m (10-ft)-diameter (bisector) composite fairing with two different lengths. Each of these fairings can be used on either two-stage or three-stage missions. The stretched-length 3.0-m (10-ft) composite fairing, designated 10L, offers more payload volume. The stretched 3-m (10-ft)-diameter composite fairing has a reshaped nose cone and a cylindrical section 0.91 m (3 ft) longer than the standard 3-m (10-ft) version.

PROPULSION

Main Engine

**A pillar of the American aerospace industry for more than four decades, the RS-27A is second to none in its class featuring a mature engine design and demonstrated manufacturing processes. The RS-27A is a single-start, fixed thrust liquid bi-propellant gas generator cycle main engine and two vernier engines. In addition to providing vehicle roll control during flight, the vernier engines each contribute more than 1,000 pounds of thrust to the main engine.

Nominal Thrust (sea level): 200,000 lb

Specifc Impulse (sea level): 255 seconds

Length: 149 in

Weight: 2,528 lb

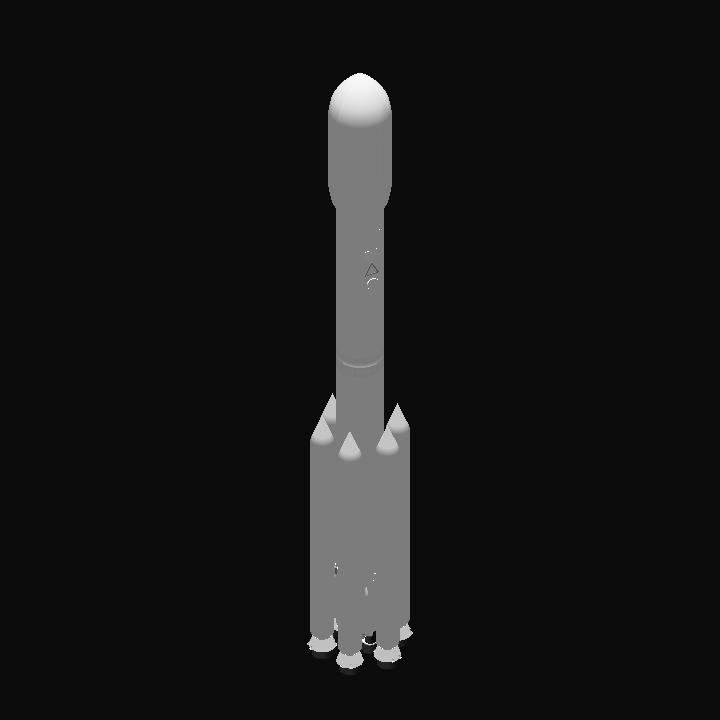

Graphite Epoxy Motors (GEMs)

The Delta II 792X vehicle configuration includes nine Orbital ATK solid rocket GEMs to augment first-stage performance. Six GEMs are ignited at liftoff; the remaining three GEMs, with extended nozzles, are ignited in flight after burnout of the first six. Ordnance for the motor ignition and separation systems is fully redundant. The 732X and 742X vehicles include three or four GEMs respectively, all of which are ignited at liftoff.

In addition to the standard 40-in-diameter GEM that is flown on the Delta II 732X, 742X, and 792X vehicle configurations, the heavier GEM-46 is made available for Delta II Heavy configurations. GEM-46 has a 46-in core diameter and burns approximately 14 seconds longer than the standard GEM-40. Both types of GEMs are flown with a fixed nozzle that is canted outboard from the vehicle centerline at 10 degrees.

GEM-40

Peak Vacuum Thrust: 145,000 lbf

Total Vacuum Impulse: 7,108,000 lb-seconds

Length: 510 in

Maximum Diameter: 40 in

Weight: 28,600 lb lbs

Burn Time: 62 seconds

GEM-46

Peak Vacuum Thrust: 199,000 lbf

Total Vacuum Impulse: 10,425,000 lb-seconds

Length: 577 in

Maximum Diameter: 46 in

Weight: 42,200 lbs

Burn Time: 76 seconds

Upper Stages

The second stage is powered by the flight-proven Aerojet AJ10-118K engine. The simple, reliable start and restart operation requires only the actuation of a bipropellant valve to release the pressure-fed hypergolic propellants, with no need for a turbopump or an ignition system. Typical two- and three-stage missions use two second-stage starts, but the restart capability has been used as many as six times on a single mission, for a total of seven burns. During powered flight, the second-stage hydraulic system gimbals the engine for pitch and yaw control. A redundant attitude control system (RACS) using nitrogen gas provides roll control. The RACS also provides pitch, yaw and roll control during unpowered flight. The guidance system is installed in the forward section of the second stage.

Second Stage

Nominal Thrust: 9,753 lbs

Specifc Impulse: 320.5 seconds

Fuel/Oxidizer: Aerozine 50/N204

Length: 105.6 in

Diameter (nozzle extension): 60.33 in

Weight: 275 lbs

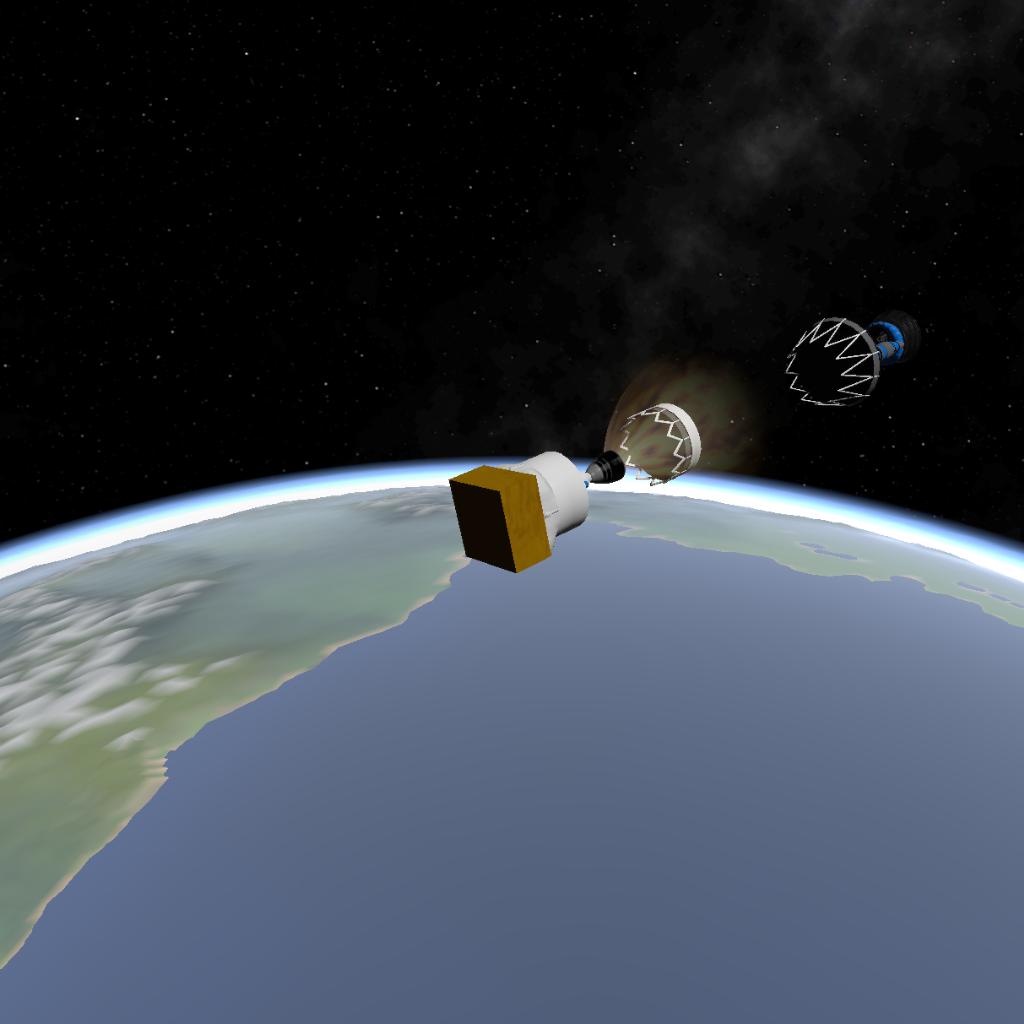

Depending on payload requirements, the Delta II series of launch vehicles offers an optional spin-stabilized third-stage motor. The flight-proven long nozzle Star 48B motor is produced by Alliant Techsystems and uses a high-energy, solid propellant and high-strength titanium cases featuring forward and aft mounting flanges and multiple tabs for attaching external hardware. The submerged nozzle uses a carbon-phenolic exit cone and a 3D carbon-carbon throat. A spin table, containing small rockets, mounts the third stage to the second stage and is used to spin up the third stage prior to separation. The third-stage payload attach fitting mates the third stage with the spacecraft.

Third Stage

Peak Vacuum Thrust: 17,490 lbf

Total Vacuum Impulse: 1,303,700 lbf-seconds

Vacuum Specific Impulse: 292.1 lbf-sec/lbm

Length: 80 in

Diameter (Maximum): 49 in

Weight: 4,721 lbs

Burn Time: 84.1 seconds

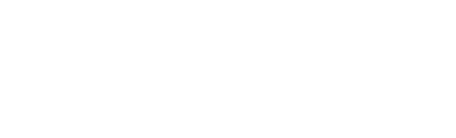

GENERAL INFO

- Created On: Android

- Game Version: 0.9.306.0

- Price: $19,448k

- Number of Parts: 184

- Dimensions: 47 m x 7 m x 7 m

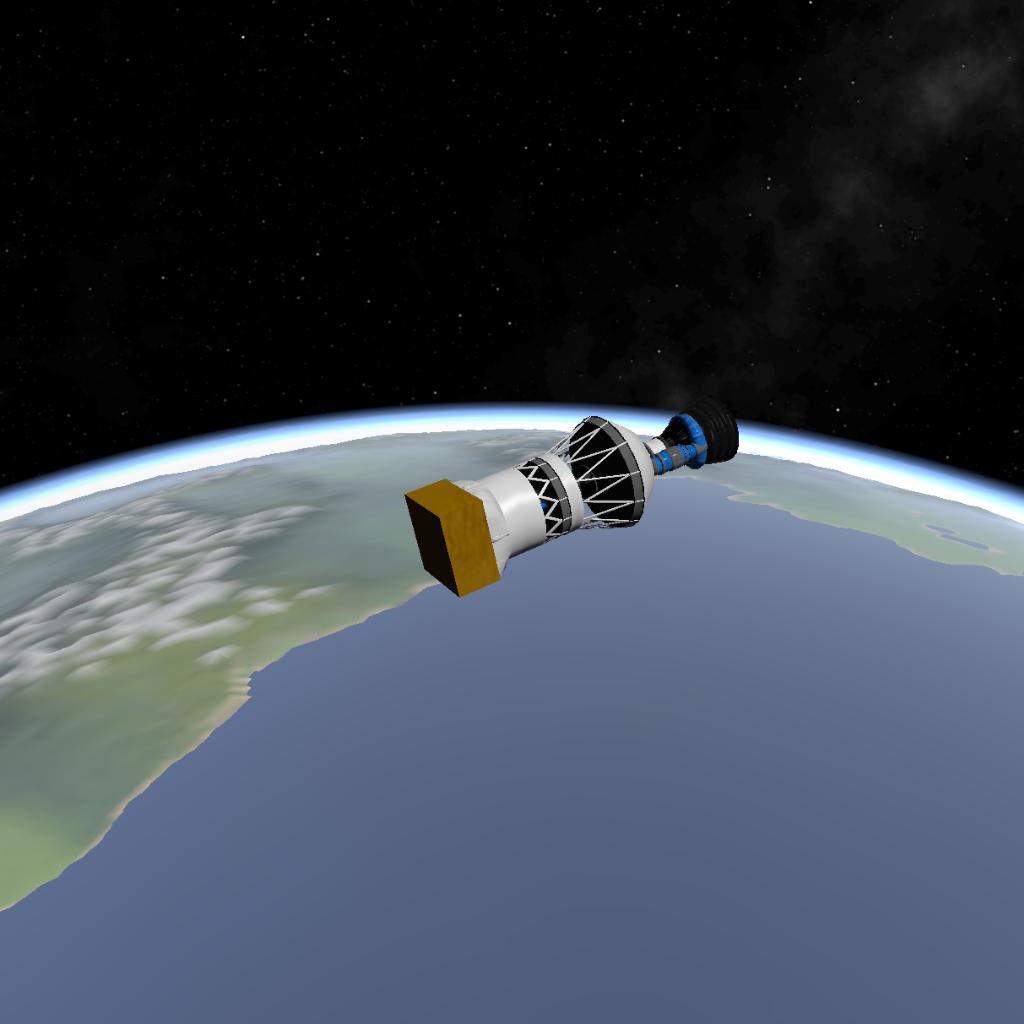

PERFORMANCE

- Total Delta V: 5.8km/s

- Total Thrust: 13.7MN

- Engines: 11

- Wet Mass: 3.22E+5kg

- Dry Mass: 32,691kg

STAGES

| Stage | Engines | Delta V | Thrust | Burn | Mass |

|---|---|---|---|---|---|

| 1 | 9 | 4.7km/s | 13.1MN | 2.3m | 3.22E+5kg |

| 5 | 1 | 417m/s | 520kN | 5s | 7,235kg |

| 7 | 1 | 719m/s | 44kN | 58s | 4,075kg |